Ukugcinwa Okuzenzekelayo & Nenkqubo Yokulinga kwakhona

-

Umthwalo omncinci AS/RS |Ugcino oluzenzekelayo kunye neNkqubo yokuFumana

UGcino oluzenzekelayo kunye nenkqubo yokuFumana ilawula indawo yakho yokugcina kakuhle ngokugqibeleleyo

yokugcina kunye ne-intra logistics.Esona siphumo siphezulu esinabasebenzi abaphantsi.Eyona ndlela ilungileyo yokusetyenziswa kwesithuba esithe nkqo.

Ubuninzi bokhuseleko lwabasebenzisi kwaye ithobela neyona migaqo yokhuseleko engqongqo.Inkqubo ithembisa umgangatho ophuculweyo kunye nokungaguquguquki.

-

Umthwalo omncinci we-ASRS ozenzekelayo kwiindawo ezincinci zokugcina iimpahla

Umthwalo omncinci we-ASRS ozenzekelayo weendawo ezincinci zokugcina izinto zikwenza ukuba ugcine iimpahla kwizikhongozeli kunye neebhokisi ngokukhawuleza, ngokuguquguqukayo nangokuthembekileyo.Umthwalo omncinci we-ASRS ubonelela ngamaxesha amafutshane okufikelela, ukusetyenziswa kwendawo efanelekileyo, ukusebenza okuphezulu kokuphatha kunye nokufikelela ngokufanelekileyo kwiindawo ezincinci.Umthwalo omncinci we-ASRS ozenzekelayo unokuqhutywa phantsi kobushushu obuqhelekileyo, ugcino olubandayo kunye nendawo yokugcina iqondo lomkhenkce.Kwangaxeshanye, ukulayisha okuncinci kunokusetyenziswa ekusebenzeni kweendawo ezisecaleni kunye nokuodola kunye nokugcinwa kwe-buffer kwisantya esiphezulu kunye nendawo enkulu yokugcina impahla.

-

Umthwalo omncinci ozenzekelayo AS/RS isisombululo sendlu yokugcina impahla

I-Miniload ye-AS / RS yolunye uhlobo lwesisombululo se-racking ngokuzenzekelayo, okuyinkqubo elawulwa yikhompyutheni yokugcina nokubuyisela iimveliso kwindawo yokugcina impahla okanye kwiziko lokuhambisa.IiNkqubo ze-AS/RS zifuna akukho msebenzi wezandla kwaye zenziwe ngobunjineli ukuba zizenzekele ngokupheleleyo.Iinkqubo ezincinci ze-AS / RS zincinci kwaye zivumela ukhetho lwezinto kwiitoti, iitreyi, okanye iibhokisi.

-

I-ASRS ene-stacker crane kunye nenkqubo yokuhambisa iimpahla zomthwalo onzima

I-ASRS pallet stacker cranes kunye nenkqubo yokuhambisa sisisombululo esifanelekileyo kwi-qty enkulu yempahla kwiipalethi.Kwaye inkqubo ye-ASRS ibonelela ngedatha yoluhlu lwexesha lokwenyani lolawulo lwendawo yokugcina impahla kunye nokuhlolwa kwempahla yokugcina.Kwindawo yokugcina, ukusetyenziswa kwe-ASRS kwandisa ukusebenza kakuhle, kugcina indawo yokugcina impahla kunye nokunciphisa iindleko zotyalo-mali kwindawo yokugcina.

-

INkqubo yeSikruphu ye-Spiral Conveyor

I-Spiral conveyors luhlobo lwesixokelelwano esizenzekelayo se-warehouse ukuhambisa kunye nokudlulisa iimpahla ukusuka kwinkqubo yokurakisha.Ingasetyenziselwa ukudibanisa iimveliso ukusuka kwimodyuli yokukhetha yamanqanaba amaninzi ukuya kumgca omnye wokuhambisa.Banokuba luncedo ekuqokeleleni imveliso kwi-spiral ukunyusa ixesha le-buffer.Ukwenziwa ngokwezifiso ukuphatha ngokukhuselekileyo imveliso eyahlukeneyo, sinokukunceda uphumeze isisombululo esinexabiso elifanelekileyo kwimisebenzi yakho.

-

Inkqubo yogcino oluzenzekelayo enezinto zeempahla ezilula

I-AS / RS yokugcinwa komthwalo omncinci yakhiwe nge-high bay racking system, i-crane ye-stacker ezenzekelayo, inkqubo yokuhambisa, inkqubo yokulawula indawo yokugcina impahla, inkqubo yokulawula indawo yokugcina impahla kunye nezixhobo zokugcina ezinxulumene nazo.Ukusetyenziswa kwe-stacker crane kukutshintsha indawo yokugcina ngesandla kunye ne-forklifts kunye nabasebenzi akukho mfuneko yokungena kwindawo yokugcina, eqonda isisombululo esipheleleyo sokugcina esizenzekelayo kwisitora.

-

Indawo yoShishino yoGcino oluzenzekelayo lweSpiral Conveyor System

I-Automatic Spiral Conveyor System lolunye uhlobo lwenkqubo yokuhambisa ngokuzenzekelayo esetyenziswa kunye nenkqubo yokurhangqa.Esi sixhobo sokuhambisa ukuphakamisa, esisetyenziswa kakhulu kwi-package, i-pharmaceutical, ukwenza iphepha, imboni yeekhemikhali, imboni yokutya kunye neminye imimandla. Njengenkqubo yokuhambisa yokunyusa, i-screw conveyor idlale indima enkulu.

-

I-automated pallet shuttle ene-crane stacker

I-automated pallet shuttle kunye ne-crane stacker luhlobo lwenkqubo yokukhwela ngokuzenzekelayo idibanisa izixhobo zokuphatha ngokuzenzekelayo kunye ne-warehouse rack.Ivumela abathengi ukuba bagcine iindleko, baphucule ukusebenza kakuhle.

-

Inkqubo ye-ASRS Crane yeePallets

Ukugcinwa okuzenzekelayo kunye neeNkqubo zokuBuyisa kwaziwa ngokuba yi-AS / RS inikezela ngokulayishwa kwe-pallet yoxinaniso oluphezulu, ukwandisa indawo ethe nkqo kwinkqubo yokusebenza epheleleyo apho inkqubo ihamba kwiindawo ezimxinwa kakhulu kunye nemiyalelo yomgangatho ophezulu.Inkqubo nganye yoMlayisho weYunithi ye-AS/RS iyilelwe kwipalethi yakho okanye enye imilo yomthwalo omkhulu, kunye nobukhulu.

-

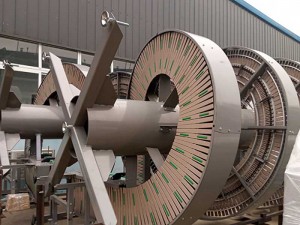

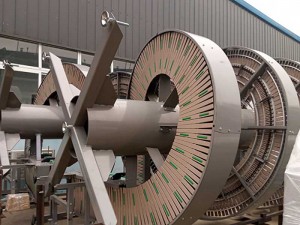

Umthwalo omncinci we-ASRS yeeTotes kunye neeKhathoni

Iinkqubo zomthwalo omncinci we-ASRS zisisombululo esifanelekileyo sokuphatha imithwalo yemisebenzi elula kwiintlobo ezahlukeneyo zeemeko zeplastiki, izikhongozeli zeplastiki kunye neebhokisi, kwaye zibonelela ngenkqubo ephezulu kakhulu yokuchola indawo yokugcina impahla.I-miniload system iyazenzekela, ihamba ngokukhawuleza kwaye isebenza ngokukhuselekileyo, kwaye inokumiswa ngokweemfuno zeprojekthi.

-

I-automatic racking system ene-radio shuttle system

I-Asrs enenkqubo ye-shuttle yerediyo yolunye uhlobo lwenkqubo yokukhwela ngokuzenzekelayo.Inokugcina iindawo ezininzi zeepalethi kwindawo yokugcina impahla.Inkqubo yenziwe nge-stacker crane, i-shuttle, inkqubo yokuhambisa i-horizontal, i-racking system, inkqubo yokulawula i-WMS / WCS.