Ukugcinwa okuzenzekelayo kunye neeNkqubo zokuFumana zinjalo - iinkqubo ezizenzekelayo ezigcina ngokufanelekileyo nangokukhuselekileyo izinto kwi-compact footprint. Bakwavumela abasebenzisi ukuba bakhuphe izinto ngokulula nangokukhawuleza xa kufuneka. Iinkampani ezininzi zenza iindidi ezininzi zokuzimela, iimpahla kumntu, ukugcinwa ngokuzenzekelayo kunye neenkqubo zokubuyisela (ASRS).

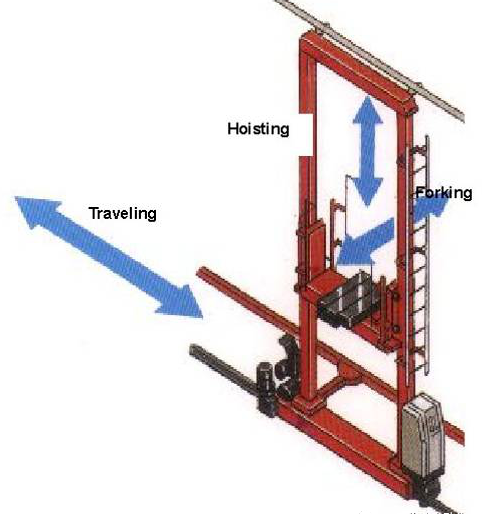

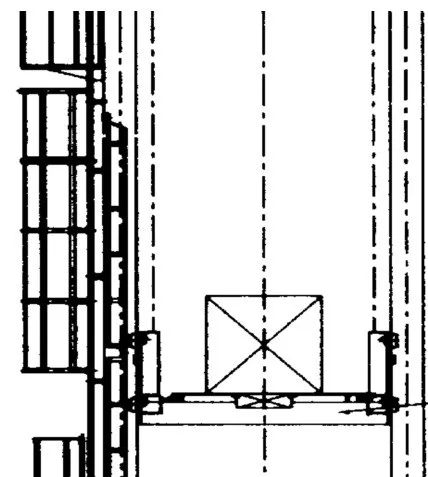

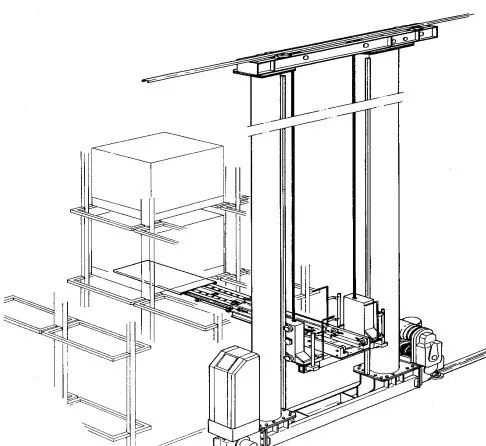

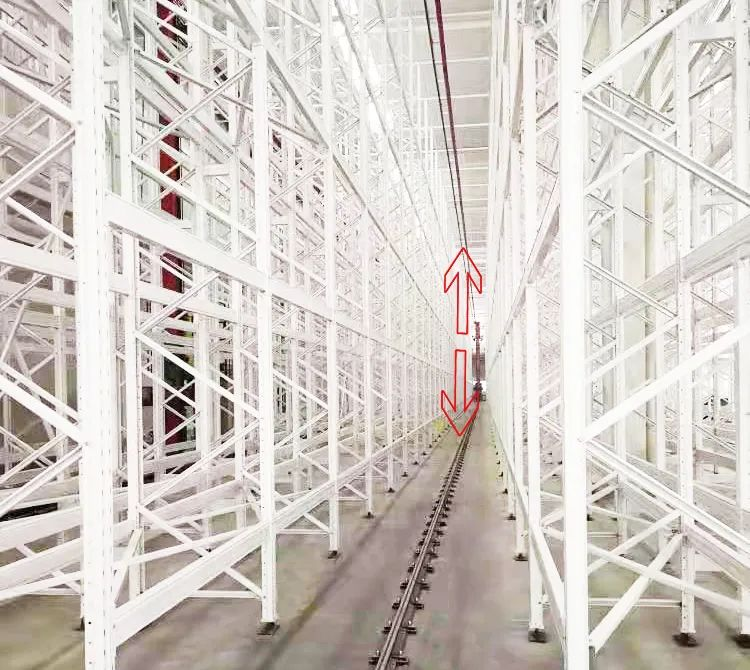

I-stacker, ekwaziwa ngokuba yi-crane yokupakisha, inokubaleka ibuye naphambili kwi-aisle ye-warehouse ene-dimensional-dimensional, kwaye igcine iimpahla ekungeneni kwendlela yokubeka kwindawo yeshelufu echongiweyo. I-stacker sisixhobo esibonakalayo se-auto-dimensional-dimensional warehouse, kwaye sisixhobo esibalulekileyo sokuphakamisa kunye nokuthutha kwindawo yokugcina i-auto-dimensional three-dimensional.

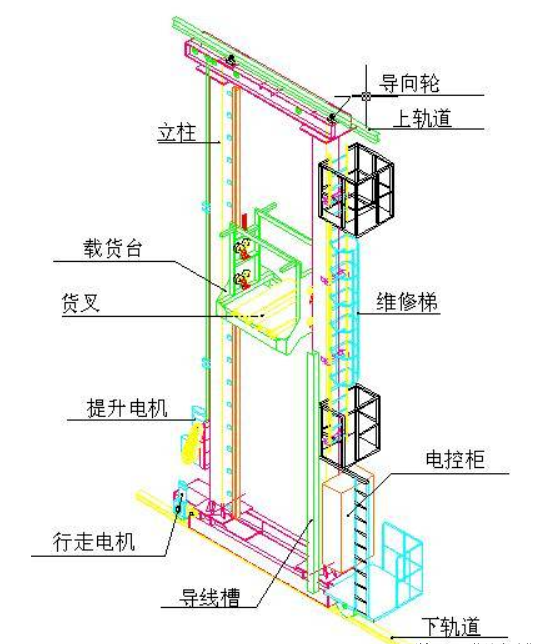

STACKER BASEumthwalo oguquguqukayo kunye nomthwalo we-static owenziwe ngexesha lokusebenza kwe-stacker uthunyelwa ukusuka kwi-chassis ukuya kumavili ahambahambayo, ngoko ke i-chassis yenziwe ngentsimbi enzima njengomzimba oyintloko odibeneyo okanye oboshiweyo ukuze ugcine ukuqina okulungileyo.

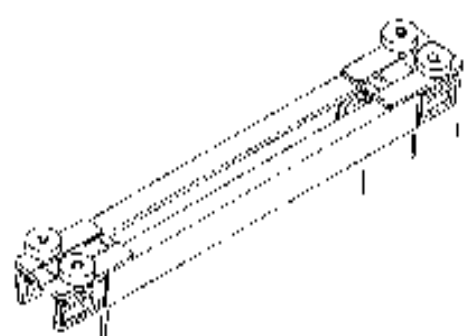

UKUHAMBA AMASHISHINIUmatshini wokubaleka ukwabizwa ngokuba yindlela esebenzayo ethe tyaba, eyenziwe sisixhobo sokuqhuba amandla, iiseti zamavili asebenzayo kunye ne-passive, kunye nezithinteli ezisebenzayo. Isetyenziselwa ukusebenza kwezixhobo zonke kwicala lendlela.

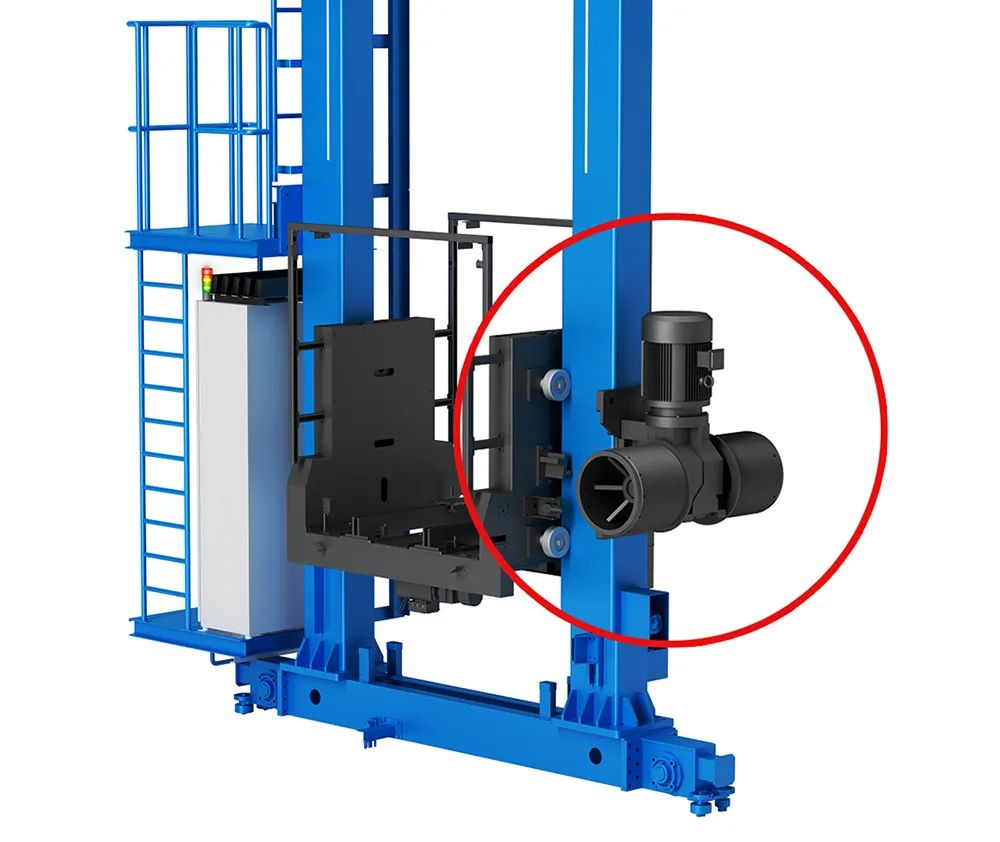

INKQUBO YOKUPHAKAMISAIndlela yokuphakamisa i-stacker ikwabizwa ngokuba yindlela yokuphakamisa, equlethwe yi-motor drive, i-reel, iqela le-sliding, intambo yocingo, njl., kwaye isetyenziselwa ukuqhuba iqonga lomthwalo ukunyuka nokuwa. Ubume obubambekayo kunye nokusebenza okuthembekileyo.

STACKER POSTI-stacker luhlobo lwe-double-mast, kodwa ukuyila kwayo imast kusekelwe kumlinganiselo ophezulu wamandla-kuya-ubunzima (i-High Strength-to-Weight Ratio) ukuthoba iziko lomxhuzulane ukuze kugcinwe ukusebenza okuzinzile; Amavili esikhokelo esisecaleni, inkxaso kunye nesikhokelo ecaleni komgaqo kaloliwe ongasentla xa uhamba; ileli yokhuseleko exhotyiselwe ukubonelela ngolondolozo.

Top BeamUmqadi ophezulu uphezulu kwikholamu ephindwe kabini, kunye ne-beam ephantsi kunye nekholamu ephindwe kabini yenza isakhiwo sesakhelo esizinzileyo, ivili elingaphezulu lesikhokelo linokuthintela i-stacker ukuba ikhuphe ukusuka kumzila ophezulu.

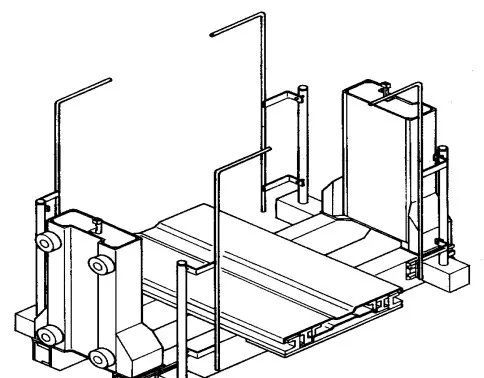

Ilayisha iQonga lokuPhakamisaIqonga lokulayisha yinxalenye ye-stacker eyamkela iimpahla kwaye yenza iintshukumo zokunyusa. Ifumaneka embindini weentsika eziphindwe kabini, imotor yokunyusela iqhuba iqonga lomthwalo ukuze linyuke lisihla. Iqonga lokulayishwa alixhotyiswanga kuphela ngempahla engaphezulu kobude, ububanzi, nobubanzi obungaphezulu kobude, kodwa kunye neendawo zokupakisha iimpahla ezibonakalayo kunye nezixhobo zokwenyani zokuthintela ukunyamezelana okanye ukugcinwa kabini kweempahla.

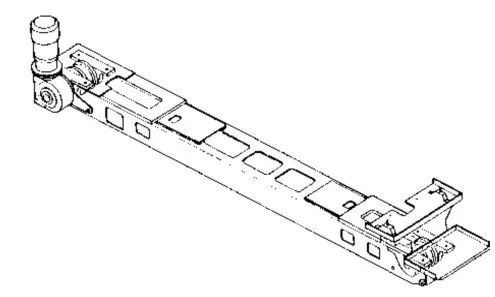

IfolokhweUmatshini we-telescopic yefolokhwe yindlela eyenziwe ngamandla okuqhuba kunye neetridents eziphezulu, eziphakathi kunye nezisezantsi, ezisetyenziselwa ukuhanjiswa kwempahla ngokuthe ngqo kwicala lendlela yendlela. Ifolokhwe esezantsi igxininiswe kwiqonga lokulayisha, kwaye iifoloko ezintathu zongezwa ngokulandelelana kwaye zihlanjululwe ngokusasazwa kwekhonkco.

IsiKhokelo esiPhezulu sikaLoliwe kunye nesiKhokelo esisezantsiumzila wesikhokelo phezulu kunye necala elisezantsi ukwenza i-crane ye-stacker ukuhamba kunye neeyile zesikhokelo.

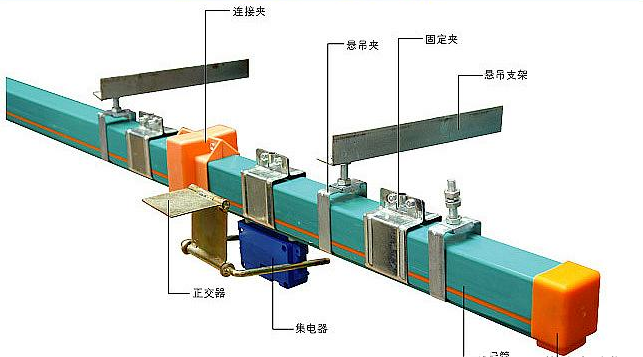

Umzila weSikhokelo saMandlaEfumaneka kwindawo engezantsi yeshelufu kwi-aisle ye-stacker, inika amandla ombane wokusebenza kwe-stacker. Ngenxa yokhuseleko, i-tubular sliding line line isetyenziswa ngokubanzi.

Iphaneli yokulawulaIfakwe kwi-stacker, eyakhelwe-ngaphakathi ye-PLC, i-converter frequency, ukunikezelwa kwamandla, iswitshi ye-electromagnetic kunye nezinye izinto. Iphaneli ephezulu ngumsebenzi wesikrini sokuchukumisa, esithatha indawo yamaqhosha okusebenza okuqala, izitshixo, kunye nokutshintsha kokukhetha. Kukho indawo yokuma ngokuthe ngqo phambi kwepaneli yokulawula, ekulungele ukulungiswa kwe-manual ye-stacker.

Ixesha lokuposa: Feb-08-2023